MySurvey – Allowing the widest possible access to sites without constraints

Site immersion provides immediate, simple, and intuitive access to your infrastructure.

Virtual reality in the true sense of the word.

- Perfect for users of all levels, from beginners to experts.

- Complete control and management of “point cloud” data, essential for advanced and expert needs.

Created in 2016, MySurvey helps industrial site operators visualize and exploit their data from 3D scans as easily as possible.

With already more than 1000 users in France, MySurvey is a software that allows projection on site and provides immediate, simple, and intuitive access to infrastructures.

It adapts to all uses, from construction monitoring to factory maintenance, and project review.

MySurvey is a software solution that requires no installation, can be accessed from anywhere, and provides the essential tools for a virtual tour of an environment.

It offers the possibility to consult various sources of information in a single software package, including point clouds, 3D models, Ultra High Definition (UHD) panoramic photos and 2D plans, as well as to reach areas and viewpoints that are rarely accessible on site.

MySurvey allows you to remotely take measurements, extract point clouds and import a wide range of 3D model formats.

It also makes it easy to carry out inspections, whatever the site’s operating conditions, thereby improving HSE (health and safety) indicators.

MySurvey offers the possibility of collaborating remotely, sharing the desired data securely, and connecting this data to digital twin management tools (PLM and CMMS).

MySurvey software enables maintenance operations to be planned, safety conditions to be analyzed in advance, and various operations to be optimally simulated.

Some advantages of MySurvey:

- Very fast and intuitive learning curve

- Solution suitable for remote work

- Compatible with various sources of 2D, 3D, and PLM data

- No software installation required

- Minimal PC configuration

- Three licensing modes to cover all use cases

- Access to specific business modules co-developed with major industrial players

Complementary modules

Several add-on modules are available to adapt MySurvey to your specific use case. These additional modules enable you to control the hazards of your projects, such as clash detection, demolition in the panoramic view, the 4D module or the compliance analysis module (DAC module).

DAC module (Detection, Analysis, Compliance)

The digital solution for compliance monitoring throughout the construction of major structures.

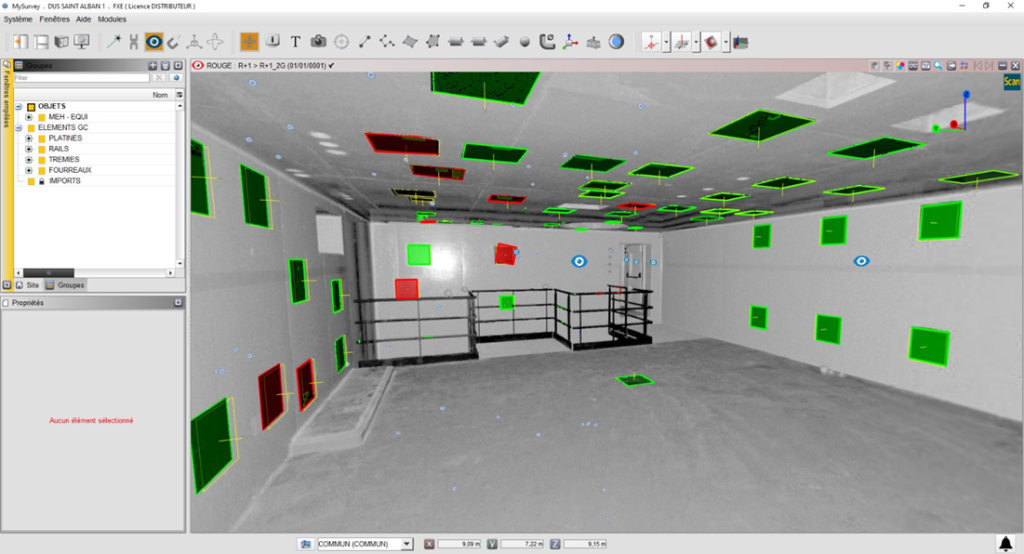

MySurvey with the DAC module is a decision-making tool that identifies construction non-conformities in 3D scans. This digital tool enables corrective actions to be taken to ensure proper coordination of the various trades involved in the installation phases that will take place on the construction site (mechanical, electrical, HVAC, etc.).

Throughout the construction phases, Cyclife Digital Solutions’ DAC module saves time and money.

The DAC module is a MySurvey-integrated business module, dedicated to the operation and conformity analysis of GC interfaces.

Its integration into MySurvey means it can be used on “basic” office computers and requires no special installation or advanced training.

The conformity control consists of:

- Checking and verifying that the anchor points on site correspond to the design plan

- Prove the conformity of anchors installed on site by calculation (if the As-Built [TQC] does not correspond to the design plan).

- Modify and/or replace non-compliant anchors, if the calculated values do not match the design plan.

The DAC module saves the user time in the first two stages of conformity control, by enabling automated visual inspection using laser scans, and batch calculation of deviations between “As Designed” and “As Built”.

DAC module features:

- Import GC interface elements whose characteristics and theoretical positions are known

- Visualize GC elements in panoramic views, plan views, and 3D views in MySurvey

- Establish their real positioning, automatically or manually

- Visually evaluate their conformity

- Output these results for exploitation in other tools.